Contact us

t :+506-633-0101

e sales.sj@saeplast.com

No Requests

Optimal for temperature retention

Optimal for durability and strength

The Sæplast DXS327 insulated seafood container is strong, long-lasting and easy to handle. It is particularly well suited for handling of fresh seafood in various settings e.g. on-board, during landing or processing. The Sæplast DXS327 container is double-walled with a PUR core and a high insulation factor. It is commonly used for handling of white fish, cod, lobster, brining scallops and clams and storing other species. The Sæplast DXS327 insulated seafood container is easy to maneuver and is accessible for both fork lift and pallet jack.

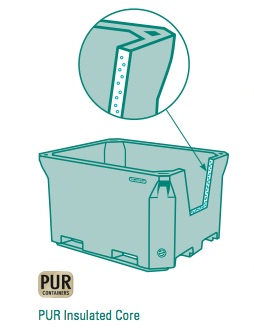

The insulation and strength factor - temperature control

Sæplast plastic containers are seamless rotomoulded double-walled containers. PUR refers to the polyurethane insulation injected into the walls of the tubs, ensuring a very high insulation factor. The primary benefit of PUR containers is temperature retention and control. For over 30 years Sæplast has developed a unique technique that ensures effective adhesion between the polyethylene walls and the polyurethane for long-lasting structure.

Sæplast storage tubs are used in many industries that require temperature control of frozen, fresh and processed food. We offer a cold

chain supply solution that is safe, efficient and hygienic. All Sæplast containers are produced from food-grade raw materials and comply with stringent food safety standards.

Sæplast insulated fish and meat tub is the safe choice for your products, your employees and your customers.

• Good thermal properties ensure steady product temperature

• The use of PUR lids with the containers further improves temperature retention

• The one-piece seamless design and smooth walls improves hygiene control

• Double-walled Sæplast containers are strong and durable

We want to help minimize transport costs for our customers. The Sæplast team recommends comparing the optimal shipping quantities in the table. The figures are based on a full container load. Keep in mind that minor variations can occur due to different stacking techniques.

| Type | Qty |

| 20' Foot container | 30 |

| 40' Foot container | 60 |

| 40' HC container | 60 |

| 53' Foot HC Truck | 100 |